- 34,8 m³ capacity

- High mobility

- Perfect tightness

- Meets requirements for CSC certification

- Stainless steel door

- Pneumatic control of discharge valve

- A solution dedicated to intermodal transport

- Container manufacturing plant meeting the ISO: 9001 : 2015 standard

Sugar containers intended for intermodal transport can be transported both on a railway and a car pla orm.

Especially recommended in rail transport in the East-West rela onship due to the transhipment of the

containers themselves and not the goods between wagons. This contributes to the excep onal profitability

of intermodal transport.

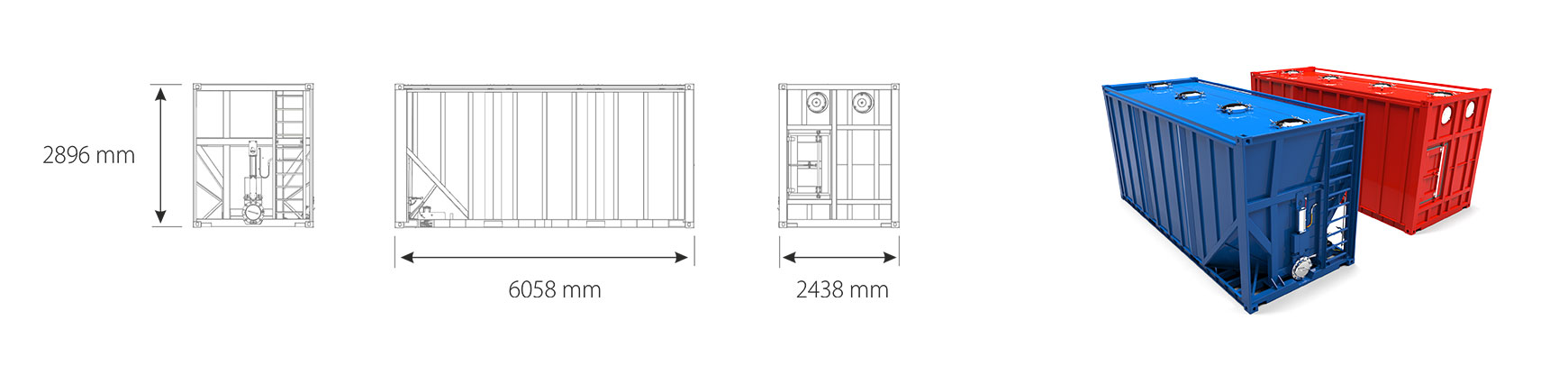

The DEVI CONTAINER FOR SUGAR IN BULK (KMTC) is used for mass transport of sugar and its temporary stationary storage. Its design enables

easy loading and unloading of goods. It has a standardized size of a 20-foot high cube container. Corner castings are welded in at the frame

corners. A set of four upper corners enables loading or unloading operations of the container, while the lower corners - fastening and securing

the container on a semi-trailer, wagon or ship. The container structure is strictly adapted to the transport of loose materials.

There are four hatches with a diameter of DN450 on the roof of the container, enabling easy loading of goods. The hatches are made of

stainless steel AlSI 304 and their gaskets certi ed for contact with food. Thanks to this type of hatches, they are not only safe under sanitary

for the transported goods, but also durable in terms of operation. All hatches have a common customs seal system and dedicated cable tension,

which reliably prevents the hatch from being opened without damaging these seals .

The interior of the container is made in a way that ensures easy unloading of the load and no possibility of keeping it in nooks and crannies.

The walls and ceiling are covered with paint certi ed for contact with food products, while the oor is covered with a durable platter

made of AlSI 304 stainless steel. Thanks to the use of a durable stainless steel plate in the place of the greatest friction of the load during

unloading and loading, there is no wear and tear of the paint coatings.

The load is unloaded after the container is tilted at an angle of 45 degrees. The goods are unloaded through a DN 300 scissor valve. In addition,

unloading is facilitated by the use of a pneumatic vibrator, which prevents the unloaded goods from stopping in the valve. The scissor valve

and the vibrator are pneumatically controlled by connecting the container to the pneumatic installation in the plant. The connection is made

with a standardized pair of quick couplers.

During loading and unloading, two safety valves ensure that the inside of the container is always pressurized which greatly facilitates these

operations.

The container is also equipped with an inspection door that allows you to check the inside of the container and its periodic cleaning.

The outside of the container is painted in color and equipped with graphics, as requested by the customer.